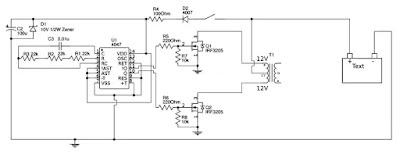

This is the Simple 100W Inverter Schematic Diagram. An inverter will convert the DC voltage to an AC voltage. In most cases, the input DC voltage is usually lower than the output voltage of the inverter while the output AC is equal to the grid supply voltage 120 volts, or 240 Volts. Lets start it.

Circuit Part List

Resistors

22K Resistor 3x

220 Ohm Resistor 2x

100 Ohm Resistor 1x

Diode

4007 Diode 1x

10V Zener 1x

IC

4047 IC + 14 Pin IC socket 1x

Capacitor

0.01uf capacitor 1x

100uf capacitor 1x

MOSFETS

IRF 3205 mosfet 2x

Varo Board

Transformer

Center Tap (CT) Transformer. Input 12-0-12, while the output refer to your standard home electricity (every county may different).

In the tutorial, it use 12-6-0-6-12 5 amp Transformer you can call it 120 VA transformer. You can use any kind of 12 -0-12 transformer.

Simple 100W Inverter Schematic Diagram

Circuit Part List

Resistors

22K Resistor 3x

220 Ohm Resistor 2x

100 Ohm Resistor 1x

Diode

4007 Diode 1x

10V Zener 1x

IC

4047 IC + 14 Pin IC socket 1x

Capacitor

0.01uf capacitor 1x

100uf capacitor 1x

MOSFETS

IRF 3205 mosfet 2x

Varo Board

Transformer

Center Tap (CT) Transformer. Input 12-0-12, while the output refer to your standard home electricity (every county may different).

In the tutorial, it use 12-6-0-6-12 5 amp Transformer you can call it 120 VA transformer. You can use any kind of 12 -0-12 transformer.

Please take a note that this inverter can handle up to 100w of load but be careful, on the 100w of load you should use Heatsinks with those mosfets.